The construction industry is a very competitive place. Every company wants to be the best and provide the most efficient service, but it’s hard to stand out when there are so many different burgeoning technologies available.Laser levels have rapidly become one of the more efficient and productive ways to streamline the process of surveying (and several other elements of construction, for that matter). However, not every laser level is going to work for every project or customer need.

What is a Laser Level?

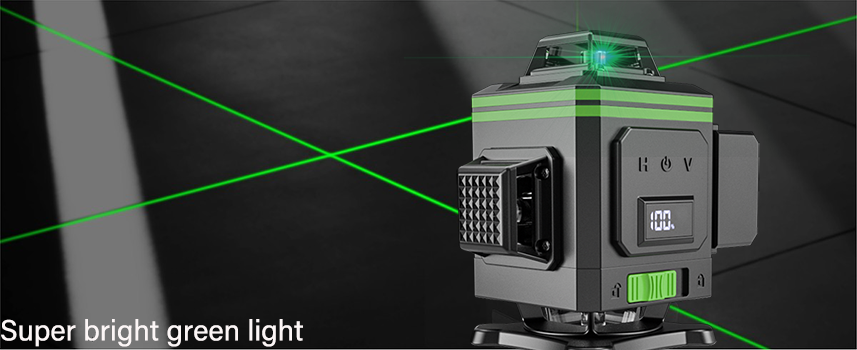

A laser level is a device that utilizes a beam of light to help make horizontal and vertical lines. It’s commonly used in surveying, construction, architecture, and some engineering disciplines.

A ‘laser level’ is actually called a laser plane or plumbline because it emits an upright plane of light from the ground, which acts like the traditional spirit level.

Although they are more commonly used in this way than others, laser levels have hundreds of different functions. They can be used to verify the horizontal and vertical position of a point on a surface, establish ‘point levels’ (horizontal reference surfaces), improve productivity by eliminating repetition, increase accuracy with their improved precision…the list goes on.

How is a Laser Level Used in Surveying?

In surveying, a laser level can be used to help surveyors establish reference points when they need to identify elevations between two points. The two most common uses for a laser level are in establishing an absolute point and elevations.

An absolute point is a reference point that doesn’t move; you can use it to determine elevation changes between any other surface points. It’s similar to the leveling rod used in the old days when they would mark a spot on the ground with a flag — as long as that flag stayed there, you could identify where you were in relation to your starting point.

The most significant difference is that with modern technology, you don’t need someone holding onto a wand or guide bolt while measuring something else. You can just set up your tripod (or position yourself) at one location and have an alignment tool automatically mark another location’s elevation relative to that fixed point.

Features to Look For in a Laser Level

How do you choose a suitable laser level? There are many features that you should look for, but here are two important ones:

- Accuracy — The standard is 1/8th of an inch per hundred feet (1:100). Some make that higher, some less, but this is the industry standard as determined by the American National Standards Institute (ANSI).

If you need more accuracy than that and your budget allows it, then get better equipment. You can always rent equipment for temporary use if it’s not quite up to snuff. However, a slight variation on this point is the vertical accuracy; some levels may advertise their horizontal accuracy (which is what we care about most) but neglect to say anything about their vertical accuracy. So, that’s another thing to watch out for.

- Speed — Laser levels come in two styles: rotary lasers and plane lasers (also called line lasers). Rotary lasers emit a light beam from a single point on the unit; they are also able to rotate 360 degrees, so you can set them up any way you like and just turn around until everything lines up. Plane lasers have an alignment vial that only allows you to face one direction simultaneously; these are more accurate but slower than rotary lasers because of their design.

As far as speed goes, plane lasers tend to be faster than rotary ones because it takes less time to move the device than it does to rotate the laser beam to each mark. However, some rotaries may be as fast or even faster because they can take advantage of gravity, and no matter where you point them, their alignment vial always points vertically.

Line lasers are typically found in surveying equipment, while rotary lasers have more applications outside of surveying, construction alignment, etc.

Corded vs. Cordless Lasers – Which Should You Get?

Surveying is a very hands-on business; depending on your specialty (topographic surveyors, for example), you could spend all day setting up reference points and measuring relative elevations between them (in which case a corded unit would be better since it will have greater power).

On the other hand, if you’re doing work for a construction company and need to measure fast on the job site, then a cordless unit would be better, as you can move around on ladders or hang off scaffolds without worrying about tripping over your power cable.

If budget is not too much of an issue, both types can serve you well. The ability to use either one will give you greater flexibility in how you choose to do your work, and it’s always nice having the best equipment possible so that when someone asks, “what kind of laser level do you have,” they won’t see any red flags.